NASHERO Joins IR4I Cluster at Paris Airshow 2023: Showcasing Aerospace Expertise

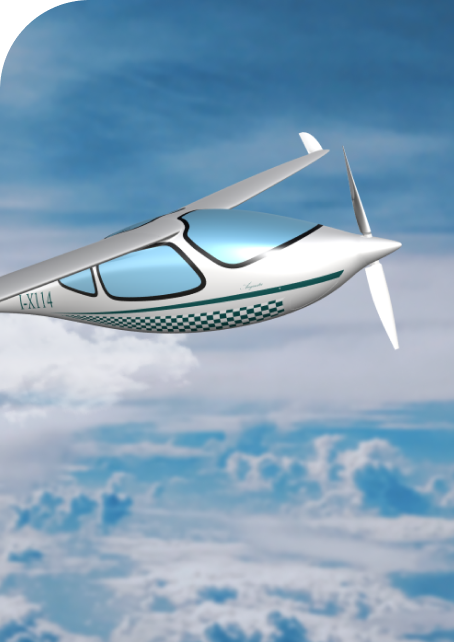

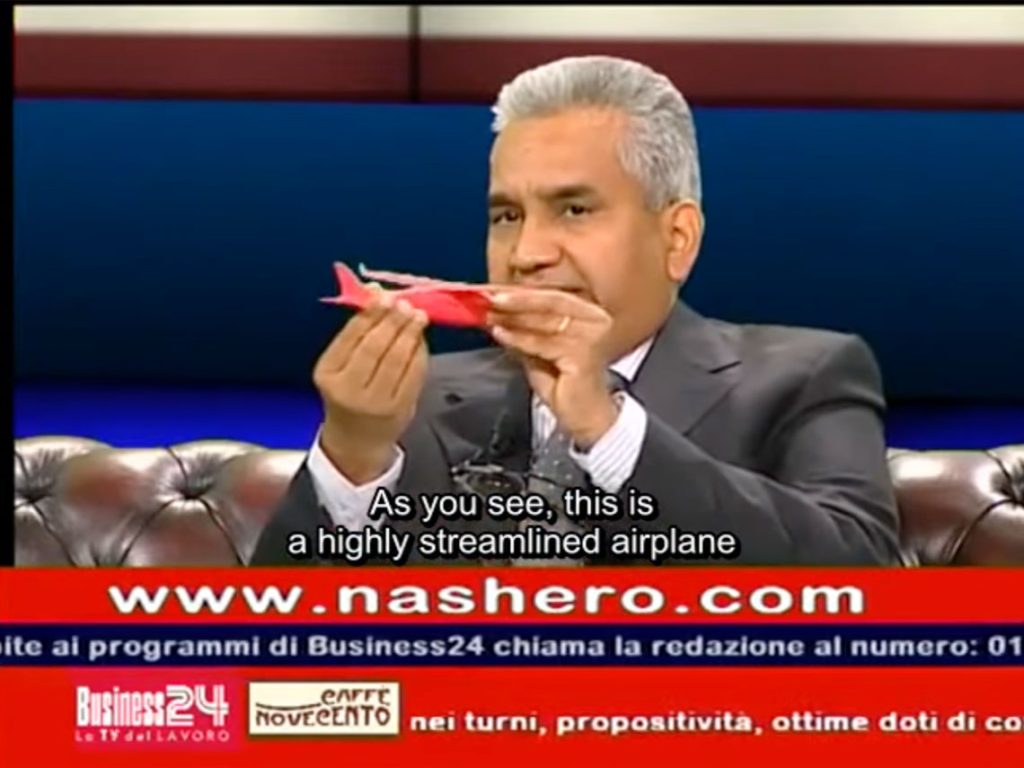

News NASHERO Joins IR4I Cluster at Paris Airshow 2023: Showcasing Aerospace Expertise 29 July 2023 admin Paris, France – June 25, 2023 | NASHERO CEO Dr. Naresh Sharma and Dr. Albertino Arteiro, University of Porto, Portugal. Precision Manufacturing Learn More Hybrid Composites Learn More