About

We began with a dream to create a safe and efficient aircraft, drawing on our extensive aerospace industry experience. Our expertise led to the development of three remarkable aircraft, now in advanced production stages with all production processes kept in-house to ensure quality.

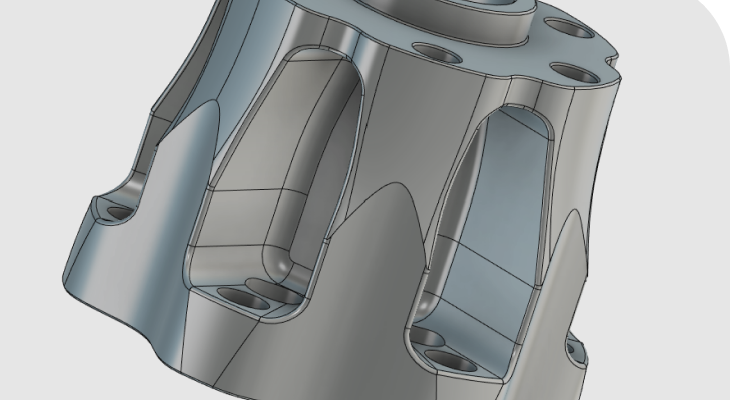

Today, we have gone beyond this original scope and offer cutting-edge composites and machining services for a variety of industries. At NASHERO, our commitment to simplicity and innovation drives us to develop no-nonsense machines that offer elegant solutions to complex problems.

With a strong focus on delivering excellence, we take pride in providing some of the best-in-class composite parts with micron level tolerances. Our cutting-edge technologies, such as ZeroVoid® technology, enable us to achieve a high fatigue life, eliminate stress concentrations, ensure superior surface quality and structural performance.

Our capabilities extend across diverse industries, and we are dedicated to solving problems for clients in the military, aerospace, medical, automobile, and high-tech sectors. Embracing precision and creativity, NASHERO stands ready to be your trusted partner in delivering top-notch solutions tailored to your specific needs.

QUALITY POLICY

- Consideration of the context of the organization, needs and expectations of interested parties, the relevant risks and opportunities, and aligning the Quality Management System (QMS) with the strategic direction of NASHERO s.r.l.

- Satisfying customer and applicable statutory and regulatory requirements

- Management of the organization, along with employee-established quality objectives and defined responsibilities for their fulfilment

- Establishing, applying, maintaining and continual improvement of the effectiveness of the Quality Management System – AS/EN9100

- Continual enhancement of customers satisfaction

- Tracking and applying new technologies and educating employees

- Careful selection and monitoring of suppliers

- Guarantee the use of safe and non-counterfeit materials

- Commitment to increasing quality, reliability, and safety of products and make-to-spec service in order to exceed customers’ expectations

- Making continuous improvement a part of every day and every job

- Ensuring that our Policy and Procedure Manuals reflect what we actually do

- Understanding how our jobs fit into the overall flow of work at NASHERO s.r.l.

- Continuously upgrading the Quality Management System in all stages ranging from order, receipt, production, and shipment, to activities after shipment.

The framework for setting quality objectives is defined in the Quality Manual.

CEO is responsible for communicating the Quality Policy to all persons working for or on behalf of the organization and making it available to the public.

CEO

DR. NARESH SHARMA

September 1, 2022

QUALITY REQUIREMENTS

- For all the duration of the supplying / contract, supplier has to guarantee the required quality standard, for which such specific supplier has been recognized and approved by NASHERO S.R.L.. Supplier has to inform NASHERO S.R.L. in due time, of any expiry or suspension of certifications / qualifications of their General Quality System.

- Supplier has the responsibility to keep an efficient management of all technical documentation given by NASHERO S.R.L.. Supplier has also to guarantee a correct management and control of the configuration of the relevant product, and has to keep all due registrations in order to guarantee traceability.

- Management of the organization, along with employee-established quality objectives and defined responsibilities for their fulfilment

- Supplier, if not already developed, shall implement a quality management system as applicable (e.g. ISO 9001, series AS/EN/JSQ 9100).

- Supplier has to keep all quality records referred to the supply to NASHERO S.R.L. (production and control), for at least 10 years from the date of production / supply of the product(s).

- Supplier has to inform NASHERO S.R.L. of any change in production processed eventually frozen, change of production plants, etc., which could impact on quality and security of the product(s).

- Supply has to be performed in accordance with product configuration required in purchase order. Any change has to be agreed and approved by NASHERO S.R.L. in advance, and its application must be indicated on shipping documents.

- Supplier must inform NASHERO S.R.L., in due time, of any non-compliance of the product. Any eventual non-compliant product might be shipped to NASHERO S.R.L. only after formal acceptance from NASHERO S.R.L.; the eventual non-conformity acceptance, will have to be indicated on transport documents.

- Supplier, when requested, shall use customer-designated or approved external providers, including process sources.

- Supplier shall prevent the use of suspected unapproved, unapproved, and counterfeit parts.

- Unless otherwise indicated in the order/contract, the manufacturing date of the products shall not exceed two years.

- The supplier must ensure that staff are aware of their contribution to product conformity and safety, of the importance of ethical behavior towards all stakeholders.

- Products have to be packed in such a way as to be protected from any damage resulting from transport and handling.

- Supplier has to guarantee free access to their sites, to NASHERO S.R.L. representatives, to NASHERO S.R.L.’s customer, and to any possible Civilian or Military Authority. A written notice will be sent in advance.

- When it is not clearly mentioned on the order, the specifications / regulations, or any other technical documentation mentioned in the purchase order itself, is meant to be referred to the last applicable revision index.

CERTIFICATIONS

AS9100D | APPROVED

- Research and development, Design, Prototyping, Production, and Sales of light aircraft.

- Design and production of composite parts and manufacturing of metal alloy parts according to customer specifications for space, aeronautics, defense and industrial sectors.

EASA DOA POA | IN PROGRESS

NCAGE

We have NCAGE codes for engaging in any work for USA or NATO countries. Our codes can be used to query our status as an OEM and provider of services to aerospace and defence companies. Our certification can be found here.

COLLABORATIONS & RECOGNITION

ASTM

IR4I CLUSTER AEROSPACE INDUSTRY, ITALY

NASHERO was invited to, and subsequently was inducted as a full member of, the most prestigious and prominent cluster of aerospace companies from the North of Italy, http://www.ir4i.it As part of the iR4i cluster, we attended the Paris le Bourget airshow as exhibitors for the first time in 2019.

CareerS

At NASHERO, we are always on the lookout for exceptional talent to join our dynamic team. We seek individuals who share our passion for aerospace innovation and possess a drive to push boundaries.

We value creativity, problem-solving skills, and a strong commitment to quality. Whether you are an aerospace engineer, composite technician, CNC machinist, or a visionary with a knack for cutting-edge technologies, NASHERO provides a conducive environment for you to hone your skills.

Join us in shaping the future of aerospace and embark on a rewarding career filled with opportunities for growth.

Get in touch or review our current openings on LinkedIn.